Microwave extraction

SAIREM’s microwave extraction equipment is the essential tool to perform high yield chemistry without overheating the compounds.

Microwave assisted extraction strengths

Extraction is a chemical process, targeting the separation (isolation) of chemical substances from the matrix. The most popular types of microwave-assisted extraction are liquid-liquid and liquid-solid.

Typically, the efficiency of extraction depends on the type of the chosen solvent and the transition rate of the chemical substance from one phase to the other. Microwave heating introduces an extra parameter as dielectric properties of the materials to influence the extraction efficiency and selectivity.

The typical advantages of MW-assisted extraction over the classical conventional methods are substantially reduced extraction time, lower solvent consumption, and improved extraction selectivity.

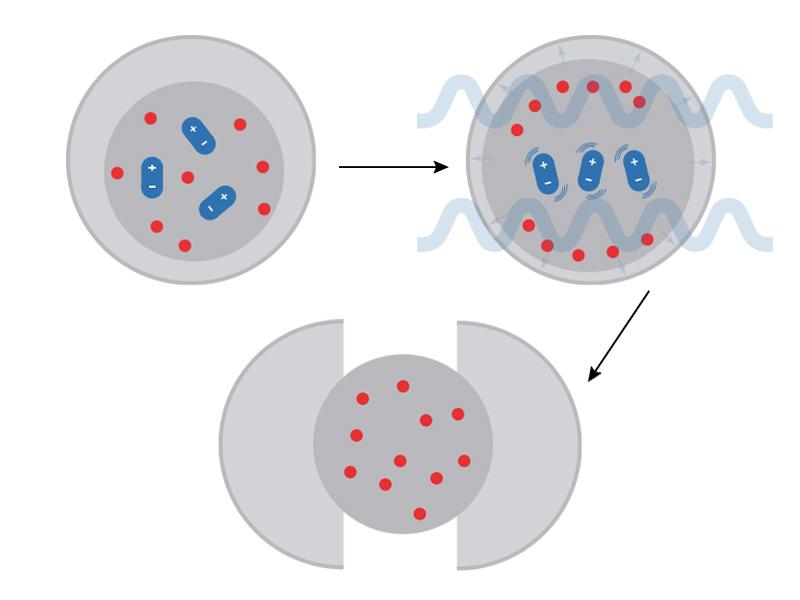

Microwave extraction mechanism

The simplest version of liquid-solid extraction is a complete dissolution of the particles or their mixtures inside a solvent. Selective extraction of the targeted chemical compounds from a solid matrix is more complicated. But both processes are determined by diffusion (diffusion is a non-equilibrium process of molecules movement caused by a concentration gradient as a driving force), but the mechanisms are substantially different.

Microwaves can substantially influence the rate-limiting step of diffusion by creating a temperature gradient between the solid particles and the solvent, resulting in faster and more efficient extraction. This temperature gradient is a result of the difference in microwave absorption properties. There is an opinion that microwaves can create a thermal gradient inside an inhomogeneous solid particle, facilitating internal diffusion rates as well. Such temperature gradients are impossible to achieve with classical conventional extraction methods.

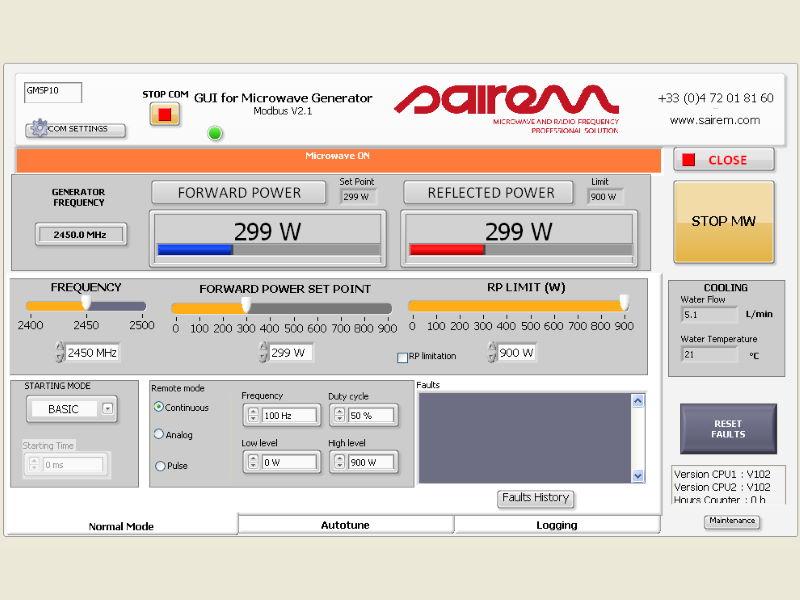

Full control of the process

We design and use high performance microwave generators, using solid state or magnetron technologies. This allows for unequaled precision of the microwave power generated and perfect reproducibility of the process.

The precise adjustment of the power makes it possible to follow the desired thermal cycle precisely.

Contact us

Advantages of our solutions

SAIREM solutions for extraction processes have a set of advantages:

- Accurate control of the process

- Rapid heating opportunity (shock treatment)

- Pulse and continuous-wave microwave modes are available

- Solid stirring solutions, which can be visually verified by the researcher

- Opportunity for visual observations of the ongoing microwave reaction, including an option for integration of real-time monitoring methods

- Real-time monitoring of the forwarded, reflected and transmitted power for power balance calculations

Discover our equipment

-

LABOTRON 6000

Microwave assisted extraction system at 2450 MHz

Complete dissolution

In the case of a complete dissolution mechanism, the interaction interface between a solid particle and a liquid is permanently moving inside the solid. During the dissolution, the transition resistance of chemical compounds into the solvent is relatively small and it can be reduced even more at a higher velocity of the solvent flow (rate-limiting step).

Selective extraction

While in the case of selective extraction of chemicals from a solid matrix, the transition resistance is much higher because the targeted chemical compounds should overcome a distance (equal on average to a radius of the particle) inside the solid structure. In such a way, the intensification of the extraction through increasing the velocity of the solvent flow is limited; and the rate-limiting step is a diffusion of chemical compounds inside the solid particle.