Food processing solutions

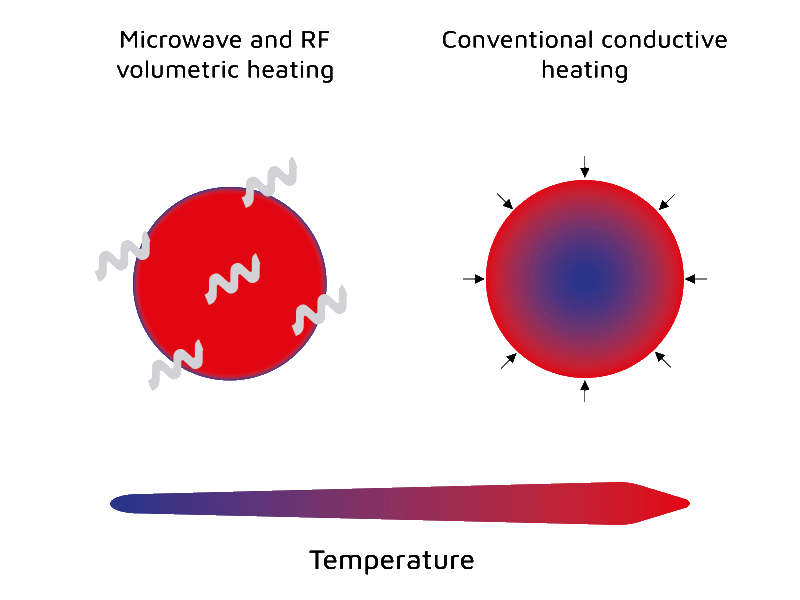

When it comes to food processing solutions, microwaves and radio frequencies represent some of the most effective technologies. They are particularly useful in many heating and baking applications, are suitable for a wide range of products and have several key advantages compared to other processes

Improve your food heating process

The microwaves and RF can considerably help you improve your food thermal process. Thanks to their heating properties, they can uniformly and quickly thaw, defrost, dry and bake food products. These faculties make them perfect solutions for food industry.

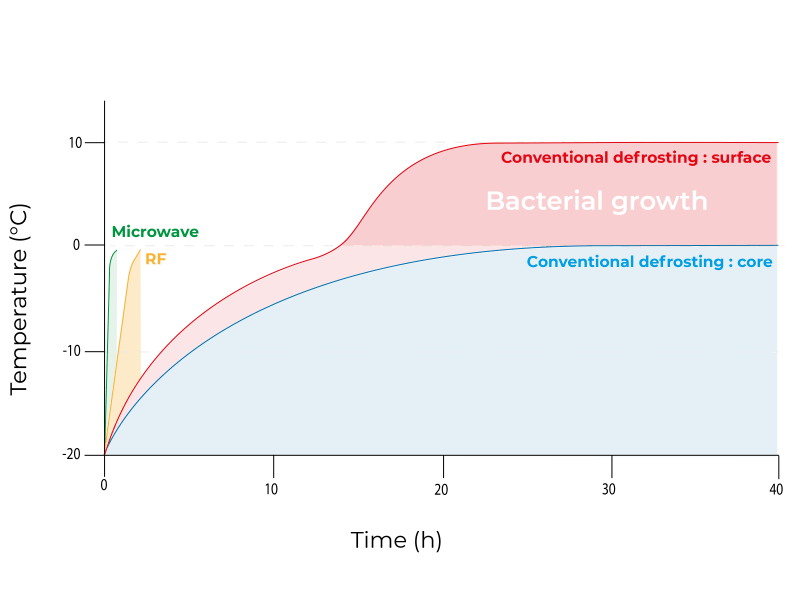

Microwaves and RF are very effective to temper or defrost many kinds of foodstuffs such as meat, fish, vegetables, fruits, butter… Depending on the type of products and your needs, RF or microwaves can be more adapted. SAIREM will help you to find the best microwaves or high-frequencies solution to improve your heating process.

Improve your food hygiene process

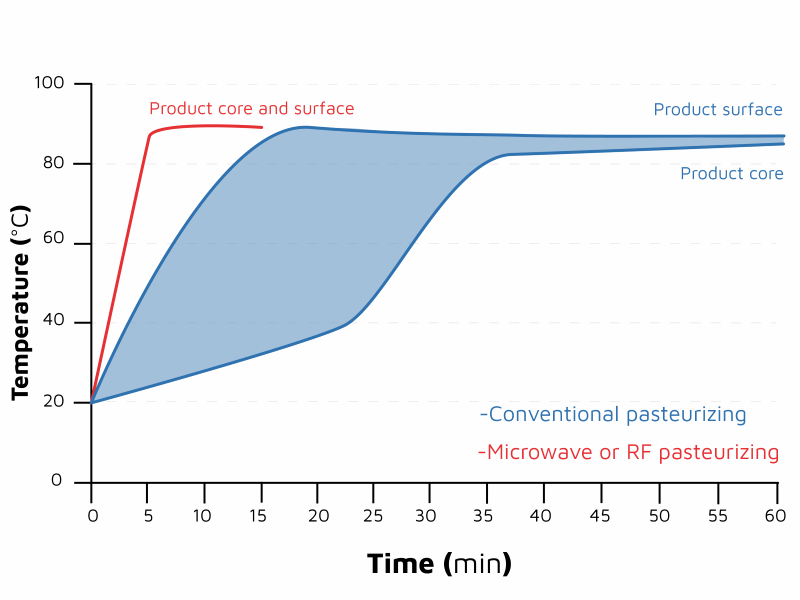

Keeping food products free from bacteria or insects is essential in food processing. The microwaves and radio frequencies are particularly effective to achieve this without altering the products. It is possible to sanitize, pasteurize or sterilize your food products retaining all their properties thanks to RF and microwaves systems.

These technologies are very useful in the hygiene process of all kinds of products such as cereals, powders, dairy products, herbs, jam…

Many advantages compared to traditional food processing solutions

The microwaves and radio frequencies are heating and drying technologies that offer the strongest advantages over previous food processing solutions. They considerably reduce the processing time, from several days or hours to a few minutes, and guarantee an uniform and hygienic heating unlike traditional way of defrosting and tempering.

The speed and uniformity brought by the microwaves and radio frequencies processes minimize the product drip losses and degradation, by completely eliminating the weight losses caused by conventional defrosting methods (which can represent up to 8% of the ingredients to be transformed). Microwave and RF systems are also less bulky than large tempering and defrosting rooms and allow you to save space in your factory.

In terms of pasteurization, you can keep all the properties of your jam or juice by using microwaves or RF systems and avoid altering the taste and colors, unlike classical pasteurization techniques.

The expert in microwaves and RF for food processing

SAIREM provide complete microwave and high frequencies solutions for food industry. We help you to find the best solution depending on your needs and your food product and we engineer for you the best configuration. Our equipment systems are totally safe and reliable.

You want to try microwaves and high frequencies to process your products ? We can easily carry out tests in our center or rent equipment to you to find the best way to improve your food process and make you save time, space and money.

Contact us