MathieuDESCHAMPS

+33 (0)4 72 01 81 60As an agri-food company you probably facing significant challenges in tempering your food products. You are likely required to manage the process of thawing large quantities of products on a daily basis.

Thawing food products is a crucial step in the agri-food sector. It prepares frozen products for processing, cooking, or direct sale to consumers. Traditional thawing methods are time-consuming and can result in significant losses in terms of quality and yield. However, with microwave technology, agri-food companies can enjoy numerous significant advantages to optimize their thawing process.

Meat, fruit, seafood, vegetables, fish, butter… We offer a full range of solutions to thaw your foodstuffs quickly and efficiently, while still preserving the organoleptic properties.

Unlike other manufacturers, SAIREM’s offer includes both microwave and radio frequency machines, so we will not try to persuade you to choose a technology based only on what we sell. Our pledge is to listen to you and analyze your needs.

Depending on the process and the characteristics of the ingredients to temper, we will supply you with the highest performance machine with the right technology and frequency for your application.

Most of the time, conventional thawing methods like defrosting rooms generate significant drip losses, which also result in a significant economic loss.

The speed and uniformity brought by the microwave and radio frequency processes minimize the product drip losses and degradation. By completely eliminating the weight losses caused by conventional defrosting methods (which can represent up to 8% of the ingredients to be transformed) you immediately improve your raw material yield. The payback can be as short as 6 to 12 months.

For example, if you defrost 20 t/day, you could save up to EUR 4 000/day thanks to our tempering solutions.

Simulate your losses

Traditional thawing methods often require a significant amount of time to be effective. However, speed is a strategic factor in the agri-food industry, and microwave thawing allows for considerable time savings.

Defrosting by microwave takes from 3 to 20 minutes instead of hours or days with traditional methods, even for large food blocks.

Your ingredients don’t need to be unpacked. They can be processed in our machines inside the plastic film, the cardboard or plastic box… You will save on labor and processing time.

You stay flexible and adapt your production in real-time thanks to the rapidity of the process. You also save space in your factory thanks to the small footprint of our equipment, as they replace large tempering or defrosting rooms. The compact size of our microwave thawing equipment saves space in production facilities, providing more room for other manufacturing steps and the buffer stock created by the traditional defrosting duration are eliminated.

Finally, our equipment capacity is highly scalable thanks to their modularity. As your activity grows, our industrial defrosting equipment can easily be upgraded.

Food safety is a significant concern for companies in the agri-food sector as it directly impacts the safety of end consumers. Food safety issues can be costly for a company and harm its reputation.

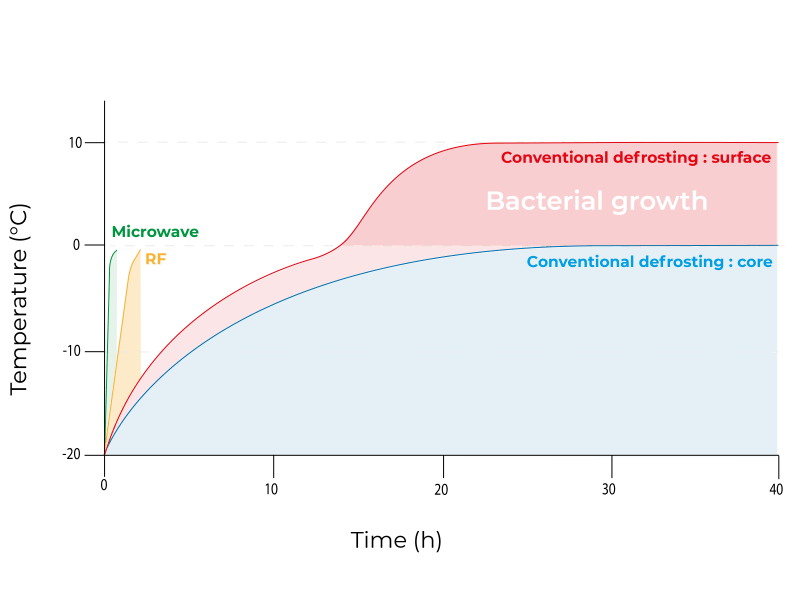

Bacterial growth will be limited thanks to the rapidity of the process. In traditional processes, your frozen ingredients take hours if not days to reach the right processing temperature, with a significant risk to food safety. The final temperature is not controlled accurately and may go above 0°C. Microwave and RF tempering is complete in a matter of minutes with perfect control of the final temperature.

On demand, and for optimal food safety, our tunnels allow you to separate the incoming and outgoing product flows to avoid cross contamination.

Microwave and radio frequency defrosting retains the organoleptic properties of your products: color, weight, taste, vitamins… Microwave technology enables quick and uniform thawing, minimizing alterations in texture, flavor, and appearance. Microwave-thawed foods retain their freshness and sensory quality, offering consumers an optimal taste experience.

The temperature homogeneity of +/- 1 ° C throughout the food block allows for better post processing of your products.

Our machines are designed for minimum maintenance. We offer comprehensive maintenance contracts and extended warranty for peace of mind.

If required, SAIREM’s customer service team operates worldwide to perform maintenance and to train your teams.

By investing in microwave technology for thawing food products, agri-food companies can benefit from improved product quality, increased productivity, significant time savings, preserved production space, and reduced bacterial contamination risks.

Do you need help improving your production process? Our experts are here to assist you in finding the best solution!

Contact us

Microwave tempering batch oven with 5 kW power.

Microwave tempering batch oven with 10 kW power.

Microwave tempering batch oven with 60 kW power.

Compact continuous microwave tempering system with a defrosting power of 35 kW.

Compact continuous microwave tempering system with a defrosting power of 75 kW.

Compact continuous microwave tempering system with a defrosting power of 150 kW.

Compact continuous microwave tempering system with a defrosting power of 225 kW.

Compact continuous microwave tempering system with a defrosting power of 300 kW.

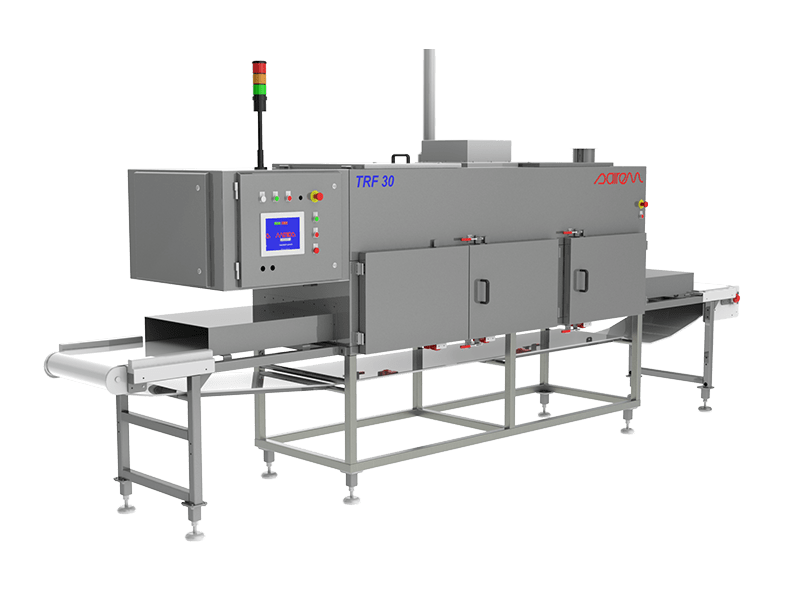

Continuous radio frequency tempering solutions with a defrosting power of 30 kW.

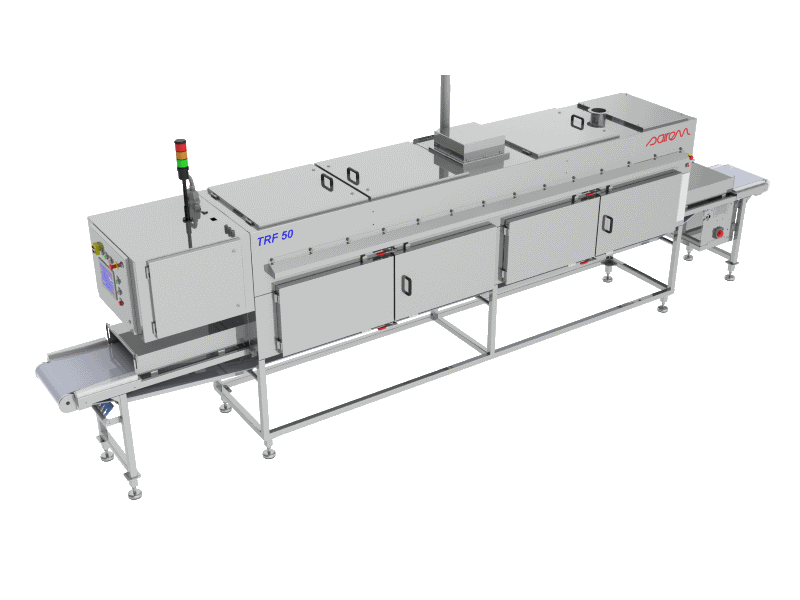

Continuous radio frequency tempering solutions with a defrosting power of 50 kW.

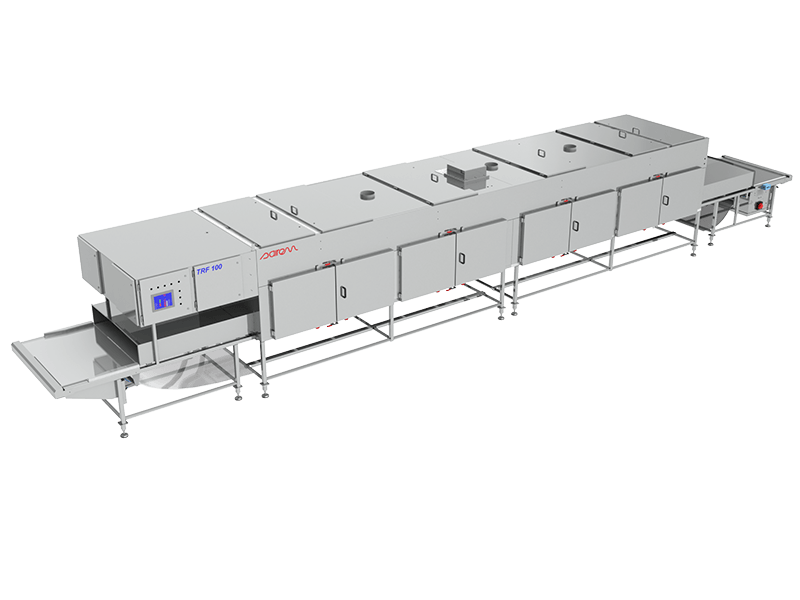

Continuous radio frequency tempering solutions with a defrosting power of 100 kW.