Microwave vs radio frequency : differences & advantages

If you are looking for a way to improve your heating process, RF and microwave technologies may be the best options. Depending on your needs, one of these two heating methods offer significant benefits. Here are some explanations to help you differentiate and understand the strengths of each technology.

How does heating by microwave or RF works ?

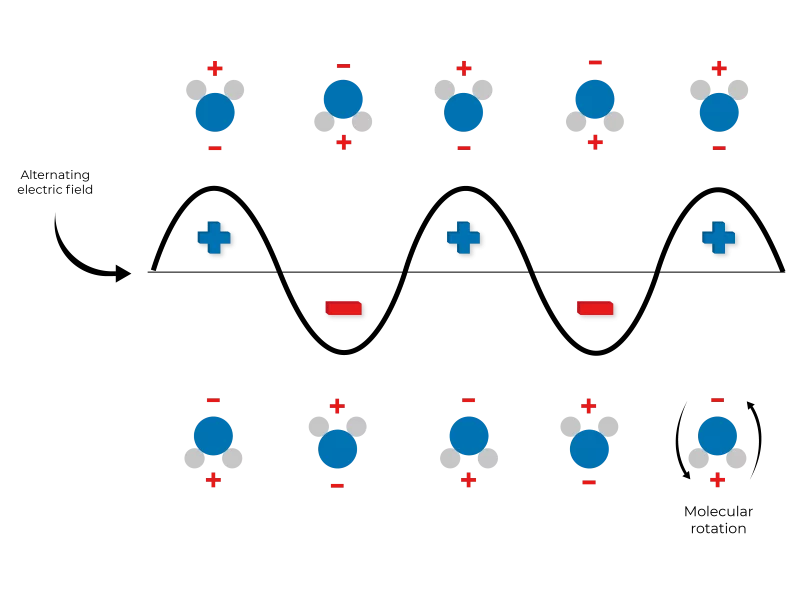

Microwave and radio frequencies are two industrial heating and drying technologies that work relatively the same way: heat is generated when the product is passed through by an electromagnetic field, due to the product dielectric losses.

This electromagnetic field create vibration and rotation of the polarised molecules inside the material. This friction between molecules increases the temperature of the material.

What are the differences between RF and microwave ?

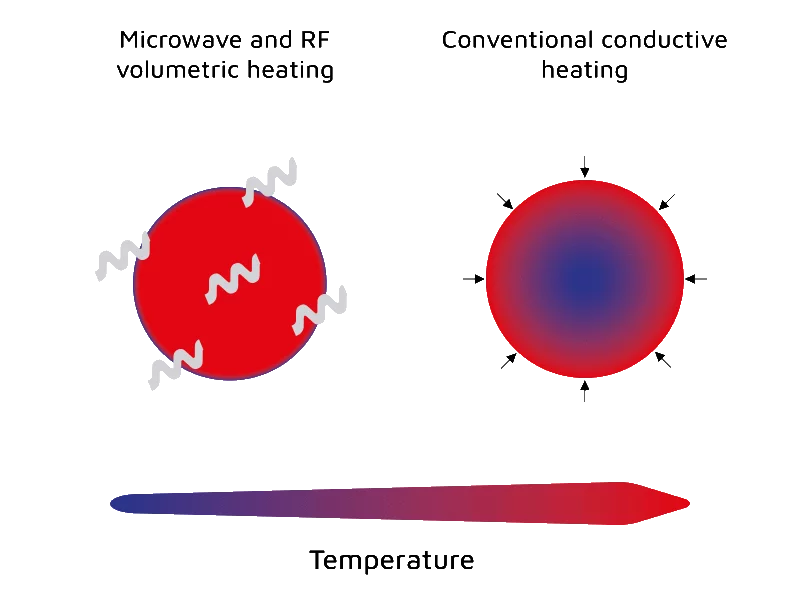

Both microwave and RF are “volumetric” heating technologies. Unlike traditional solutions, who heat the product from the outside to the inside by conduction, they heat the whole product uniformly.

The main difference between microwave and RF is related to their wavelenght, which has impact on how the energy travel and is transmitted to the treated product. Each technology has its own advantages.

Advantages of radio frequency technology

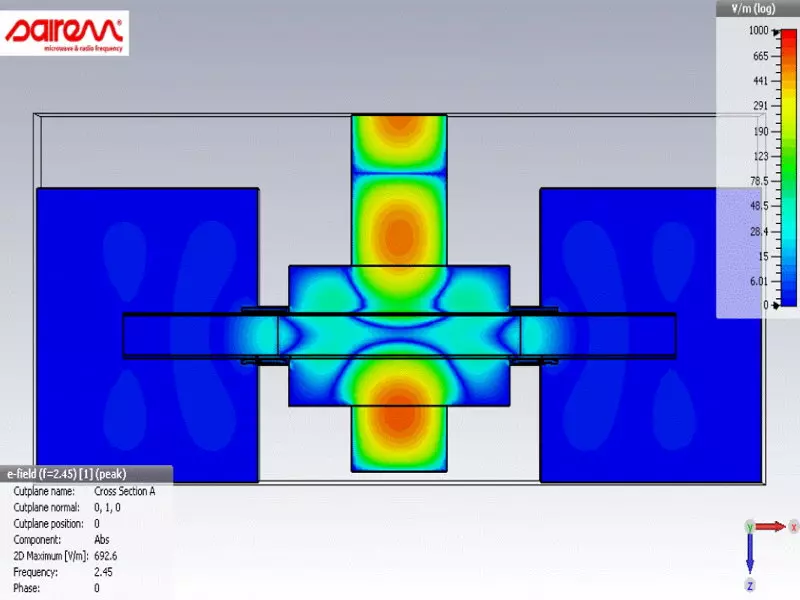

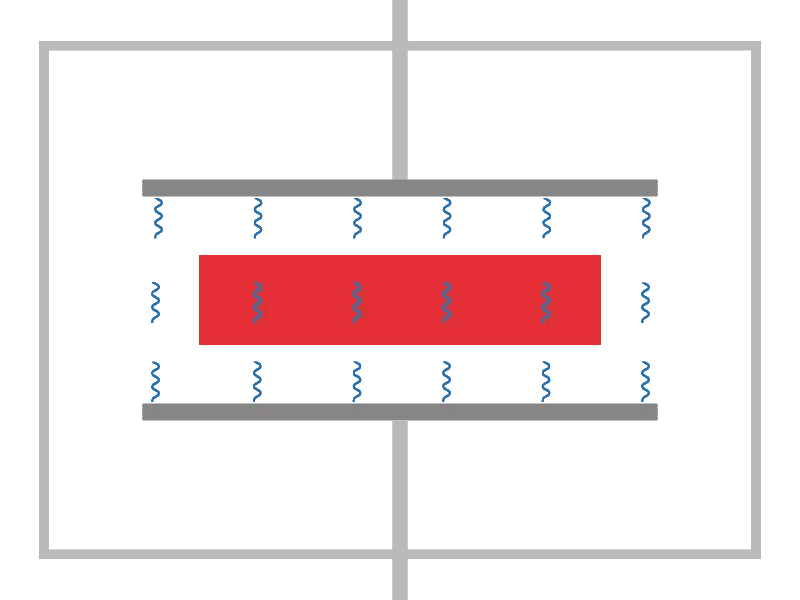

Generated thanks to a RF generator, radio frequencies move from an electrode to the other inside the cavity and pass through the treated material. This capacity makes them more effective on products of regular size and shape which are thus heated uniformly.

Thanks to their longer wavelength, around 10 m, radio frequencies can penetrate deeply into the material and thus heat thick products. They heat more slowly than microwaves and thus make it possible to treat more delicate products which require a slower heating.

Radio frequency are usually preferred for heating and drying of regular shape products like textile, wood, powders, processed food …

Contact us

Advantages of microwave technology

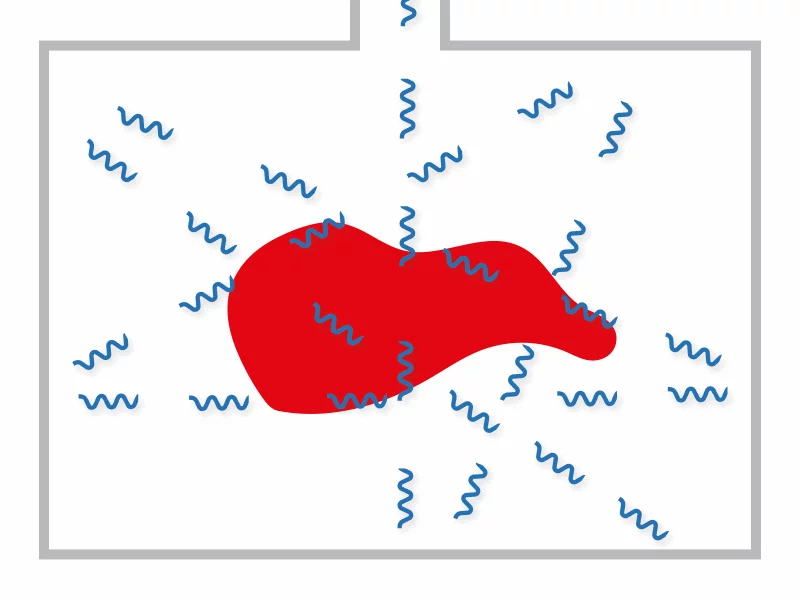

Microwave energy is generated thanks to a microwave generator and must be guided by waveguides up to the cavity. Their wavelength vary between 10 cm to 30 cm depending on the frequency used. They are highly effective for treating different types of products at high speed, and in particular those which have an irregular shape, like pieces of meat for example.

Thanks to their ability to heat uniformly, microwaves are often used to quickly heat or dry industrial material or food stuffs. They are higly efficient for the pasteurization of liquid product and sanitization operations.

Why using radio frequency or microwave technologies ?

Radio frequencies and microwaves are both useful to improve heating processes in industry and food industry. Even if they have different capacities, they still are the best way to to heat materials while preserving their quality, taste and colour.

They can be used to heat, temper, cook, dry, sanitize, pasteurize and numerous other applications. Unlike conventional technologies, they avoid drip losses when used for defrosting food, are both very safe and can be combine with traditional heating method for a perfect thermal process.

Our expertise on microwave and radio frequency

SAIREM masters the both technologies and their respective advantages. Depending on your products, your budget and your actual process, we provide you the best RF or microwave solutions to meet your needs.

If you have questions about RF and microwave technologies effectiveness on your product, we offer you to make a test in our laboratory.

Contact us