Drying of insulating aerogel

Our customer, a french company specialized in super-insulating materials, needed a solution to dry silica aerogel by evaporating the ethanol used in the process

Customer needs

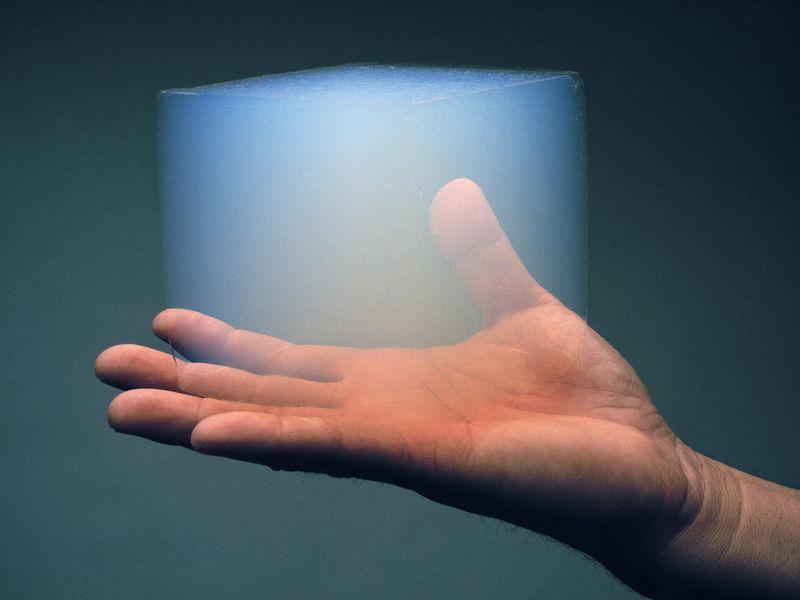

Our client develops very high performance insulating materials from the family of silica aerogels. They are composed at 95% of air which make them really light. These materials, mainly from space research, have the highest known thermal insulation properties. They are mainly used for isolation in construction or electronics.

The manufacturing process involves the use of ethanol, a highly flammable product, which must be evaporated while ensuring total safety during the operation. Traditional processes, such as supercritical drying at high pressure and high temperature, are therefore difficult to implement under these conditions.

Main constraints

The main difficulty encountered during the process is to operate in an ATEX environment in order to avoid any accident. The goal was to evaporate the ethanol used in the manufacturing process by heating the product to the precise temperature 78 °C.

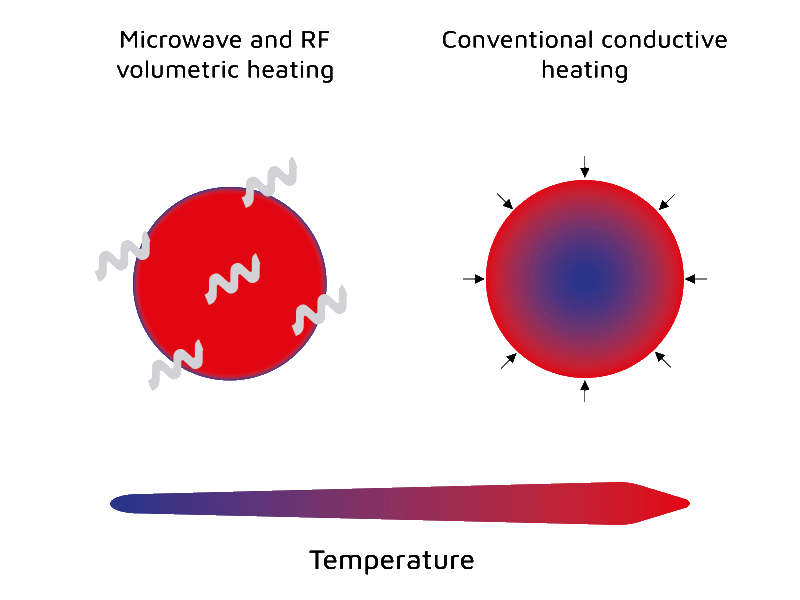

The first solution that come to mind is to use hot air or infrared, to heat and dry the aerogel. But as it is a super-insulating material, it is impossible to use these traditional technologies as they would be totally inefficient. That’s why SAIREM designed a custom solution to dry the aerogel, by using the volumetric heating properties of microwaves.

Solution proposed

To meet the customer’s ATEX constraints and avoid any risk of accident, SAIREM has designed a tailor-made solution composed of a 100 kW microwave generator located outside the building, waveguides pressurized under nitrogen to avoid leakage of gaseous ethanol, and finally from a reactor under nitrogen atmosphere.

The 915 MHz microwaves frequency was selected, as this wavelength is adapted to penetrate, heat and dry large volumes of products homogeneously.

Key benefits

SAIREM’s engineers helped this customer to find the best solution to meet this specific need. By using the homogeneous and volumetric heating properties of the microwaves, our equipment is able to heat and dry the whole silica aerogel mass from core to surface, even with this super-insulating material.

We provided our customer a perfectly designed and safe microwave drying system with a power of 100 kW, capable of evaporating 250 kg/h of ethanol, and reducing it’s rate from 80% to less than 1% in the final aerogel.

Contact us