What are the different pasteurization processes for ready meals?

The process of pasteurization is one of the most common food preservation methods. Not all technologies are equal to meet the demand of new consumer trends, specialy when it comes to ready meals and packaged products.

A growing challenge in the food industry

More than a sanitary issue, the pasteurization of packages products is now a focus for the food industry, as consumers want safer and healthier products without use of preservatives or additives, specially when it comes to ready meals. Consumers are also looking for taste and goodness in their food.

Facing this growing demand, new pasteurization methods are emerging. It is essential to choose the most adapted technology, suitable for the product to pasteurize but also preserving most of the organoleptic properties of the processed foods.

Pasteurization of packaged products

There are many pasteurization techniques to processdifferent types of ready meals products. Among the most common, we can mention in particular:

- Autoclave: heat treatment of food by injection of steam or spraying water in a sealed pressure chamber.

- Pasteurization on plates: spraying of hot water then cooling by spraying cold water.

- High pressure pasteurization (HPP): treatment of products in an enclosure filled with pressurized water at room temperature.

- Microwave pasteurization: inside-out and fast heating of food products, without the use of water.

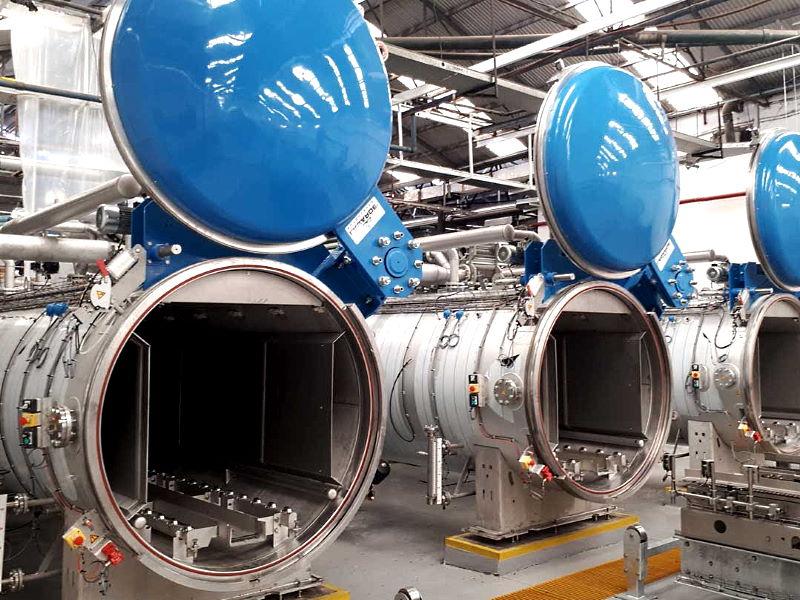

Autoclaves

The retort is a traditional process used in the food industry for pasteurization of ready meals. It heats the products to the desired temperature by injection of steam or spraying water in a sealed pressure chamber.

The process duration to reach the required temperature at the products heart (conduction) is long . It can also have an impact on nutritional qualities, taste, and color of the processed foods which is often overcooked with this process

Spiral pasteurizer

Spiral pasteurizators offer continuous process that uses spraying of hot water on the packaged food. The product is therefore heated by conduction from the outside to the inside.

The ready meals are loaded onto the belt and transported to the different treatment areas (heating, cooling …). The maximum treatment temperature is 90°C.

High pressure pasteurization

The high pressure pasteurization (HPP) involves applying high pressure, 4 000 to 6 000 bars, on a product for 2 to 5 minutes. To do so, the packaged food is inserted in a prezzurized enclosure, filled with water at room temperature.

This technology retains the nutritional properties of foods well, which are not degraded by high pressure. However, it is an expensive, not continuous, and complex technology.

Microwave pasteurization

In terms of pasteurization process, microwaves represent an efficientsolution for processing many ready meals products of diverse textures (pumpable products, powders, etc.). It also better preserves the organoleptic properties of the products treated than most other technologies.

Microwave technology offer multiple benefits:

- Speed: the product is processed quickly in just a few minutes while conventional processes can take 40-60 min.

- Gentle heating: the targeted temperature is controlled, which prevents overheating of the products, for perfect product quality.

- Significant space saving: microwave solutions take up much less floor space than otheer solutions, and this is a continuous process.

- Energy savings: 100% of the microwave energy generated is transmitted directly into the product without conduction phenomenon.

- Environment friendly: fully electric solution, for no carbon emission at the production plant.

Need help to find the best solution ?

Our free microwave and radio-frequency guide for food applications will help you to better understand these technologies, and find the solution the most adapted to your needs.

Download your guide