Microwave drying of insects

In recent years, insects have gained increasing importance in the agri-food industry, generating growing interest in their potential as an alternative source of protein. As dietary habits evolve and the global demand for protein continues to grow, insects are emerging as a promising solution to address these challenges.

Our customer needed a quick and efficient solution to gently and homogeneously dry meal-worms, mainly intended for the pet food industry. Discover how our microwave drying equipment fully meet their needs.

Challenges of insect drying for the agri-food industry

Insects such as crickets, mealworms, grasshoppers, and crickets are rich in proteins, vitamins, minerals, and essential fatty acids, making them a increasingly studied and utilized source of nutrients in the agri-food industry. Moreover, they require less water, arable land, and feed compared to traditional livestock, making them a more environmentally sustainable option. Insects can be raised on a large scale and reproduce quickly, offering efficient and cost-effective production.

The use of insects in the agri-food industry also brings significant economic advantages. The production costs of insects are often lower than those of traditional livestock, which helps reduce expenses related to food production. Furthermore, diversifying protein sources with insects opens up new business opportunities and fosters innovation in the agri-food sector.

However, despite the potential benefits of insects in the agri-food industry, challenges remain. One of the main issues lies in the processing and preservation of insects. Due to their high water content (60%), insects are prone to deterioration and microbiological contamination when not properly dried. Microwave drying technology emerges as an effective solution to address this problem and find solutions for agri-food companies.

Former insect drying process

Our customer is a company specialized in dried insects alternatives for petfood and fertilizer. It has the aim of producing insect-based food in the future, now that it is authorized for humans.

Their previous drying equipment was delivering poor performances. The goal was to improve the drying process to fully meet all their quality requirements (homogeneity, color, texture, taste…) and reach their targeted humidity level.

This customer needed to dry few hundreds kilos per hour of mealworms with a homogeneous, gentle and efficient process. Their product, initially containing around 60% of water, need to be dryed up to 6% to 8% of humidity.

As an expert in microwave drying solutions, SAIREM sought a dryer that would meet the specific needs of this customer.

Insect drying solution offered

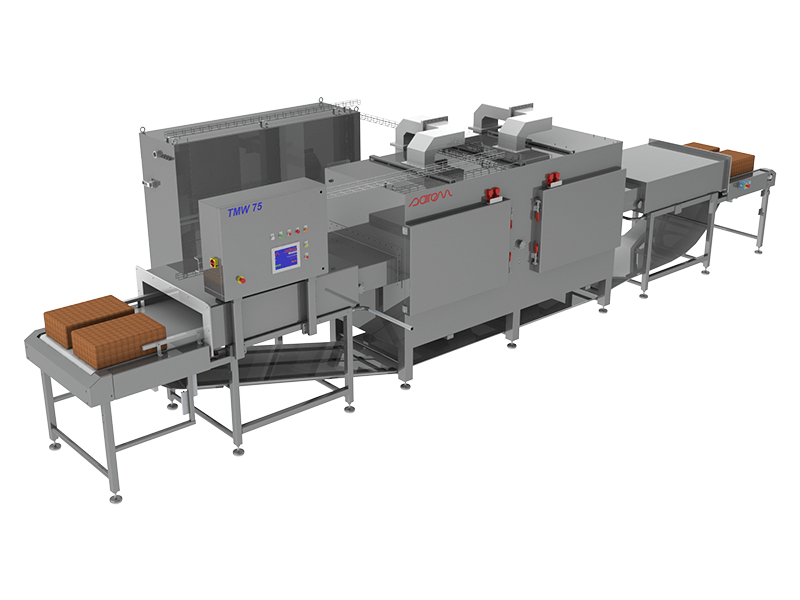

According to the amount of water to evaporate from the product, SAIREM designed a 75 kW microwave power tunnel with an air extraction system.

This compact and continuous solution can evaporate up to 75 kg of water per hour, which allows to dry up to 140kg of mealworms per hour. As microwaves travel through and heat the entire product’s mass, the full process takes less than 10 minutes.

Unlike conventional batch process like freeze drying or hot air oven, microwaves offer a very quick, uniform and flexible solution within a perfect controlled process. This process allows to preserve the organoleptic properties thank to a drying temperature bellow 100°C, enhancing the product’s quality and safety.

Our microwave solution has allowed our client to daily dry a large quantity of insects in a record time, without altering the properties and nutrients of the product.

Microwave drying key benefits

Innovative products require equally innovative solutions. Microwave drying represents an effective alternative for insect drying for several reasons:

- Speed: by drying the product in just a few minutes, our equipment saves precious time for the company and allows to increase your production rate.

- Quality: by preserving the organoleptic properties of the insects, the final product quality has been greatly enhanced compared to the previous equipment used.

- Appearance: the insect integrity and color is preserved due to the quick and gentle process.

- Savings: this process allows to save time and energy, therefore money.

As a food industry professional, if you are seeking an efficient insect drying solution, our experts are available to assist you in finding the suitable option for your process.

Contact us

Need help to find the best solution ?

Our free microwave and radio-frequency guide for food applications will help you to better understand these technologies, and find the solution the most adapted to your needs.

Download your guide