How to pasteurize liquids in-line ?

Pasteurization is one of the main food preservation methods. Used by numerous food industries worldwide, pasteurization helps preserve food from microorganisms and significantly extends its shelf life.

Discover the most common continuous heating methods to pasteurize liquid and pasty products.

The pasteurization process

The pasteurization process is old and has been used for many years to preserve food, or even to make it suitable for consumption.

Democratized in the 19th century, the process of pasteurization was named after Louis Pasteur, who demonstrated that harmful microorganisms in wine could be rendered inactive by applying heat at temperatures below its boiling point. This breakthrough discovery revolutionized the field of food preservation and paved the way for safer consumption practices.

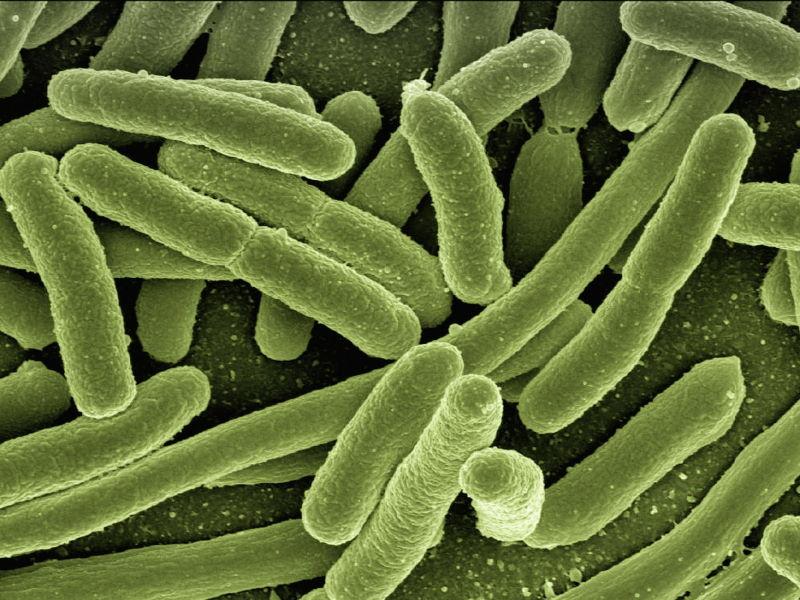

Pasteurization is a preservation process that aims to limit the deterioration of a food product by greatly (but not completely) reducing the presence of pathogenic microorganisms responsible for the deterioration of food.

This process consists in subjecting the food to high temperature, high pressure, or electric impulsion for a determined period of time. By subjecting the food to high temperature, the growth of bacteria, yeasts, pathogenic microorganisms and enzymatic activity is slowed down and the product can thus be kept cold for longer. The objective of this treatment is to exceed the heat resistance threshold of bacteria and micro-organisms in order to eliminate as many of them as possible.

Liquids pasteurization process

Although the pasteurization process can be used on solid foods such as meat products, eggs, nuts, ready meals or bakery items, it is predominantly employed in the food industry to treat liquid products, especially milk. The process of pasteurizing liquids involves subjecting the liquid product to high temperatures. This is what distinguishes this process from low-temperature pasteurization used to sanitize non-liquid foods.

Pasteurization of liquids is used on many food products to preserve it. It is a technique generally used on drinks such as milk, dairy products, fruit juice, etc. It can also be used to pasteurize pasty products such as jam or honey.

Conventionally, pasteurization is carried out with a heat exchanger whose principle is the energy transfer through a wall (surface).

How does liquid pasteurization process work ?

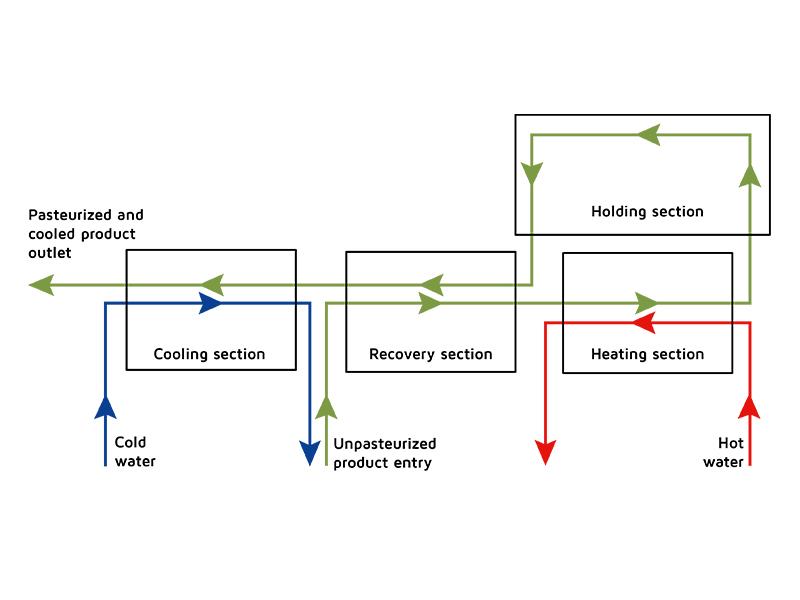

A pasteurizer is composed of four sections that allow the liquid to undergo four stages of processing:

- recovery or preheating

- heating to the pasteurization temperature

- temperature holding during the requested time

- finally the optional cooling step before packaging

Most of pasteurizers works with heat exchangers, who consist in transferring thermal energy from one liquid, often water, to another. The heat energy mostly comes from steam or hot water generated by a gas boiler or an electric source.

The pasteurization by microwave

As an expert of microwave generators and supplier of industrial solutions for food companies SAIREM has developed a fast and efficient solution with a reduced footprint: an in-line microwave heater. This equipment works with both liquids, pasty, or grain products. It is currently used to heat the product to the temperature you need within a few seconds, or to start a pasteurizing process. Depending on product’s, power, and requested temperature raise, it can process up to 12 tons of product per hour.

Microwave pasteurization is a fast process that can be carried out continuously, offering significant logistical advantages in terms of product handling and production planning. Our proven technology ensures optimal homogeneity, thus allowing for a reduction in the pasteurization temperature of food products.

Unlike traditional pasteurizers, microwave pasteurization solutions offer several advantages:

- Speed: The microwave pasteurization process is completed within seconds.

- Space-saving: For the same capacity, microwave pasteurization equipment requires less floor space compared to traditional pasteurizers.

- Energy efficiency: Thermal energy is directly transferred to the product without losses to the surrounding atmosphere.

As a food industry professional, if you are seeking an efficient liquid pasteurization solution, our experts are available to assist you in finding the suitable option for your process.

Contact us

Need help to find the best solution ?

Our free microwave and radio-frequency guide for food applications will help you to better understand these technologies, and find the solution the most adapted to your needs.

Download your guide